World’s Largest Nighttime Solar Module Electroluminescence (EL) Testing Identifies Causes of Six Figure Losses for Major O&M

Onsite EL Testing of 180,000 Modules

In 2018, Clean Energy Associates (CEA) was engaged by a large Operations and Management (O&M) provider to conduct electroluminescence (EL) imaging at a 56.49 MW project in England. The supplier of this project was a Tier 1 Chinese supplier that had already delivered more than 20 GW of solar modules to customers in more than 90 countries.

The O&M had previously discovered a decrease in power output that was resulting in six figure losses but lacked the ability to conduct EL imaging on a project of this size. CEA worked with the manufacturer and the O&M provider in advance to determine the image resolution which would be high enough to detect the defects and acceptable for the manufacturer to accept as proof of a warranty claim.

As part of the largest nighttime onsite EL imaging test ever conducted at the time, CEA inspected 90% of the modules over a three-month period.

While the situation could have been averted had CEA carried out quality assurance during manufacturing, EL imaging tests revealed a significant number of the modules were affected by cold soldering issues or microcracks.

Importance of EL Testing

Many defects that affect solar module performance are not visible to the human eye. These defects can include microcracks, poor/cold soldering, and broken cells, among others. For this reason, solar module manufacturers typically perform EL imaging tests to identify these defects and remove them from the production line.

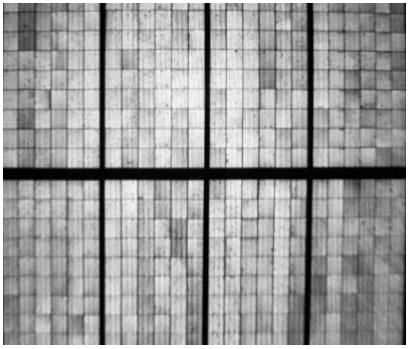

Example of electroluminescence (EL) image of solar module

EL images work as a sort of x-ray for the module, highlighting defects not visible to the human eye. Some of these defects have the potential to affect the performance of the module, and when scaled up, can end up costing end-users significant financial losses in lost output.

For this reason, manufacturers typically perform EL testing twice during the production of solar modules due to the importance of catching these defects. However, despite in-house EL imaging, even Tier 1 solar manufacturers regularly misjudge or fail to identify EL defects, resulting in the defective modules being shipped to the client if a third-party quality assurance partner is not used.

EL Imaging Reveals Microcracks and Cold Soldering on Solar Modules

Following the on-site testing, CEA analyzed the results and identified two main defects in a large number of the modules. Those defects fell into two categories:

Cold Soldering Issues

Microcracks

In one location accounting for almost 19MW of the project’s total output, 80% of the modules were affected by these two defects.

Cold Soldering Defects

It was found that cold solder joints were present in 5% of the total modules. Cold soldering occurs when the temperature during the soldering process is not high enough. And as was the case for this project, the cold soldering was interfering with the connection between the cell ribbon and cell tab – preventing electricity from flowing and causing a loss in power output.

If left unnoticed, cold soldering has the risk of developing into hot spots, which further reduces the power of the module and has the potential for fire risk.

EL image of a solar module with cold soldering defects

Microcracks

Microcracks are cracks in the silicon wafers formed due to damage either during manufacturing, shipping, installation, or operation that have the potential to develop into a loss of active area and reduce the output of not only the modules containing microcracks but the entire strings containing a defective module. Over time microcracks can lead to diode activation or hot spots that represent a safety risk.

EL image of solar modules with microcrack and broken cell defects

Manufacturer Agrees to Warranty Claim

Because CEA had worked out the criteria for replacing modules in advance, once the defective modules had been identified, it was possible to have discussions on a technical level without the distraction of value at stake.

This highlights the importance of having the contract in both English and Chinese, as the miscommunication in the translation might cause issues when working out warranty claims. What counts in the end is that the decision-makers and the technical team in China understand everything rather than relying on words written in English.

Because the defects were easily demonstrated to be defects caused during production, the manufacturer agreed to replace more than 5,000 modules with a current market value of almost half a million (500,000) euros.

Importance and Cost Savings of Inline Production Quality Assurance

This case highlights the importance of and cost-saving nature of utilizing a third party to perform quality assurance. Although the manufacturer replaced 5,000 modules, the EPC and O&M service provider was left with the majority of expenses including:

Initial lost yields from lower power output

Commissioning third-party (CEA) to perform field testing to identify the defects

Additional installation work

Personnel expenses related to warranty claims

During a third-party production monitoring, the entire production process from Bill of Materials review to instrument calibration, warehouse inspections, and production monitoring among others is performed.

During inline production monitoring, CEA checks 100+ items and parameters including the soldering temperature, EL imaging, and the peel-off force between the cell ribbon and the solar cells. In this case, inline production monitoring would have cost around one-fifth of what the field testing ended up costing.

In another warranty claim case, proper upstream due diligence would have cost only a tenth compared to the downstream testing that had to be carried out to detect faulty modules, but this depends on the type and magnitude of the on-site inspection. The added value of an upstream audit is not just in cost savings but in the increased level of confidence in the quality of your purchased modules.

CEA provides technical due diligence and engineering services for solar and storage clients around the globe who are financial institutions, project developers, EPCs, IPPs, and PV power plant owners. Upstream, our team of engineers travel to factories around the globe to conduct in-factory quality assurance via audits, production monitoring and pre-shipment product inspection.

CEA has demonstrated expertise in preventing microcracks in shipped modules, identifying microcracks in the field, and taking proactive actions before microcracks cause power loss or hotspots.

Feel free to reach out to us to inquire further about our upstream and downstream services.