Avoiding Costly Defects in Energy Storage: A Developer’s Guide to Quality Assurance

by Jeff Zwijack

This article was originally published in MESIA Mid-year Solar Report 2025

In this article, originally published in MESIA's Mid-year Solar Report 2025, Jeff Zwijack, Associate Director of Energy Storage at CEA, explains that most defects in battery energy storage systems arise during system-level integration rather than cell or module production. He highlights how thorough supplier vetting, robust factory quality assurance, and comprehensive factory acceptance testing can prevent these costly issues and ensure reliable, long-term system performance.

Figure [1]: Distribution of all BESS Findings

Battery energy storage systems play an increasingly central role in grid reliability and renewable integration across the Middle East. Yet, behind this rapid expansion lies a less visible challenge: a significant portion of defects are introduced during final system integration, long after battery cells and modules have been manufactured.

If such issues go undetected before shipment, they can delay commissioning, reduce system performance, and create lasting operational headaches. Fortunately, they’re also highly preventable if developers take the right steps at the right time.

What can go wrong

Inspection data from hundreds of energy storage system integration facilities worldwide reveals that a majority of quality issues, more than 70%, emerge not during cell or module production, but during system-level integration. This is the stage where battery modules are containerized and systems are assembled.

Figure [2]: Share QA Findings by Manufacturing Stage

The most frequent problems arise in key subsystems such as thermal management, fire suppression, control systems, and auxiliary circuits. Some of the most common categories of defects include:

Fire detection and suppression (28% of system-level findings): Systems failed to detect heat or smoke due to miswired sensors, while others couldn’t deploy extinguishing agents when needed. In some cases, emergency abort buttons didn’t function at all.

Thermal management (15%): Faulty components such as valves and compressor boards led to coolant leaks or complete system shutdowns — issues that, if missed, could accelerate degradation or trigger thermal events.

Auxiliary circuit panels (19%): Improper assembly or wiring caused failures in power distribution and communications, disrupting normal system operation.

Capacity test failures (6%): Subtle wiring issues introduced resistance that limited system output. These problems were difficult to detect without functional testing, yet have major implications for project performance and revenue.

Figure 3: Distribution of System-Level Findings

Visual caption: These issues typically stem from a combination of factors, such as rushed assembly timelines, manual labor, and inadequate documentation, rather than a single point of failure.

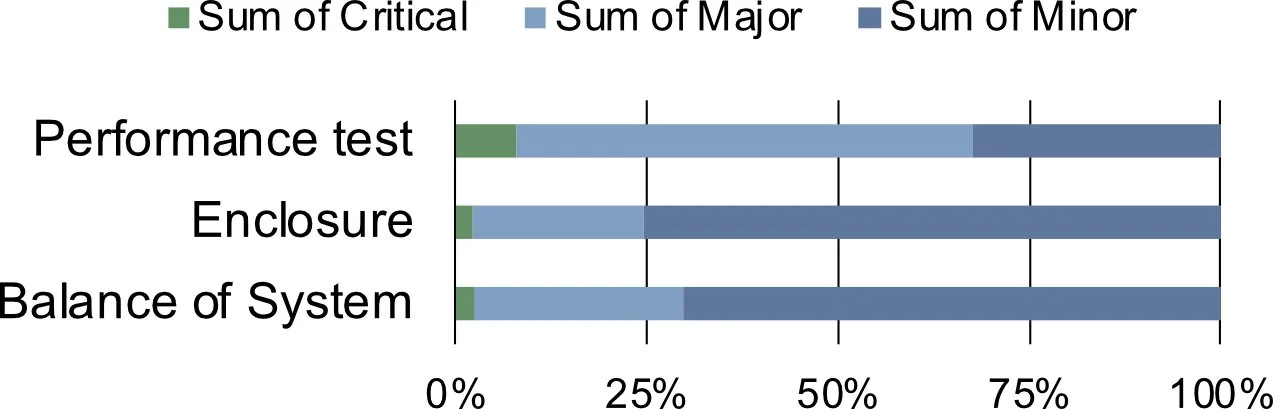

Figure 4: Severity Scale of System-Level Findings

Visual caption: While critical defects made up a small share of systems-level issues, a majority of performance test failures were considered major, indicating that they will reduce the battery’s functionality or impact safety in either short or long term.

How to catch defects before they ship

The most effective way to prevent system integration defects from reaching project sites is to catch them during production — before the containers are even loaded for delivery. That’s the role of third-party factory quality assurance (QA).

Independent inspections evaluate the actual units being built for a specific project, not just generic product samples or one-time vendor audits. Inspectors check wiring, component placement, and system functionality in real time, identifying issues that internal quality control teams may miss.

This allows manufacturers to resolve problems at the factory, rather than after delivery — when corrections are slower, more expensive, and can jeopardize project timelines or revenue.

Factory acceptance testing (FAT) adds another safeguard. Conducted just before shipment, FAT verifies the complete functionality of each system: thermal regulation, fire suppression, auxiliary circuits, and software communications. FAT gives developers a last chance to detect wiring or configuration problems that might otherwise go unnoticed until performance is impacted in the field.

Together, robust factory QA and FAT offer developers confidence that their systems will arrive on-site ready to perform — without costly surprises.

Figure 5: Severity Scale of System-Level Findings

Visual caption: Other critical defects included main circuit panel issues, BMS functionality, grounding mechanism defects, poor wiring and cabling arrangement, and water ingress issues.

Strengthening supplier selection and contracts

Preventing quality issues starts well before the factory floor. Developers who evaluate suppliers rigorously — and who structure clear, enforceable contracts — can avoid many of the integration problems that show up later in production.

Key considerations include a supplier’s historical performance and quality discipline. More experienced integrators tend to have stronger process controls, clearer documentation, and more mature quality management systems (QMS). Data from third-party audits and historical defect rates can provide essential insights into real-world supplier reliability.

Clear contract language is just as vital. Vague or generic scopes leave room for misunderstanding. Developers should clearly define equipment specifications, testing requirements, acceptance criteria, and documentation obligations. Contracts should also include remedies for non-conformance, such as rework, replacement, or financial compensation.

Responsibility must also be clearly delineated. If a defect emerges during commissioning, who investigates and who pays? Ambiguity on these points often results in costly delays, strained relationships, or even legal disputes. A well-structured contract ensures accountability and enables developers to maintain quality control throughout the supply chain.

Don’t skip the final checks

Even with a quality supplier and comprehensive QA, the final stretch of the project still carries risk. That’s why developers should continue validating quality through delivery and commissioning:

Before shipment, review all test reports and inspection records for issues of concern.

Confirm that any non-conformances found in the tests and inspections were corrected — not just noted.

Upon delivery, perform inbound inspections to verify that the containers match what was approved at the factory. Examine for proper labeling, documentation, and transit protection.

During commissioning, employ functional testing to confirm that each subsystem — thermal management, fire suppression, auxiliary panels — is performing as expected under real-world conditions.

By staying engaged throughout the full lifecycle, from supplier evaluation to system commissioning, developers can significantly reduce the likelihood of costly surprises and ensure their energy storage investments deliver reliable, long-term performance.

Jeff Zwijack is Associate Director of Energy Storage at Clean Energy Associates.