Weather-proofing Wisdom

by Paul Wormser

This article was originally published in pv magazine - December 2022 edition.

Going above and beyond can drive up costs when it comes to solar project features such as racking height and module glass strength. But in an ever-warming world, it could take only one extreme weather event to destroy investments. Clean Energy Associates VP - Technology Paul Wormser offers a few tips for developers.

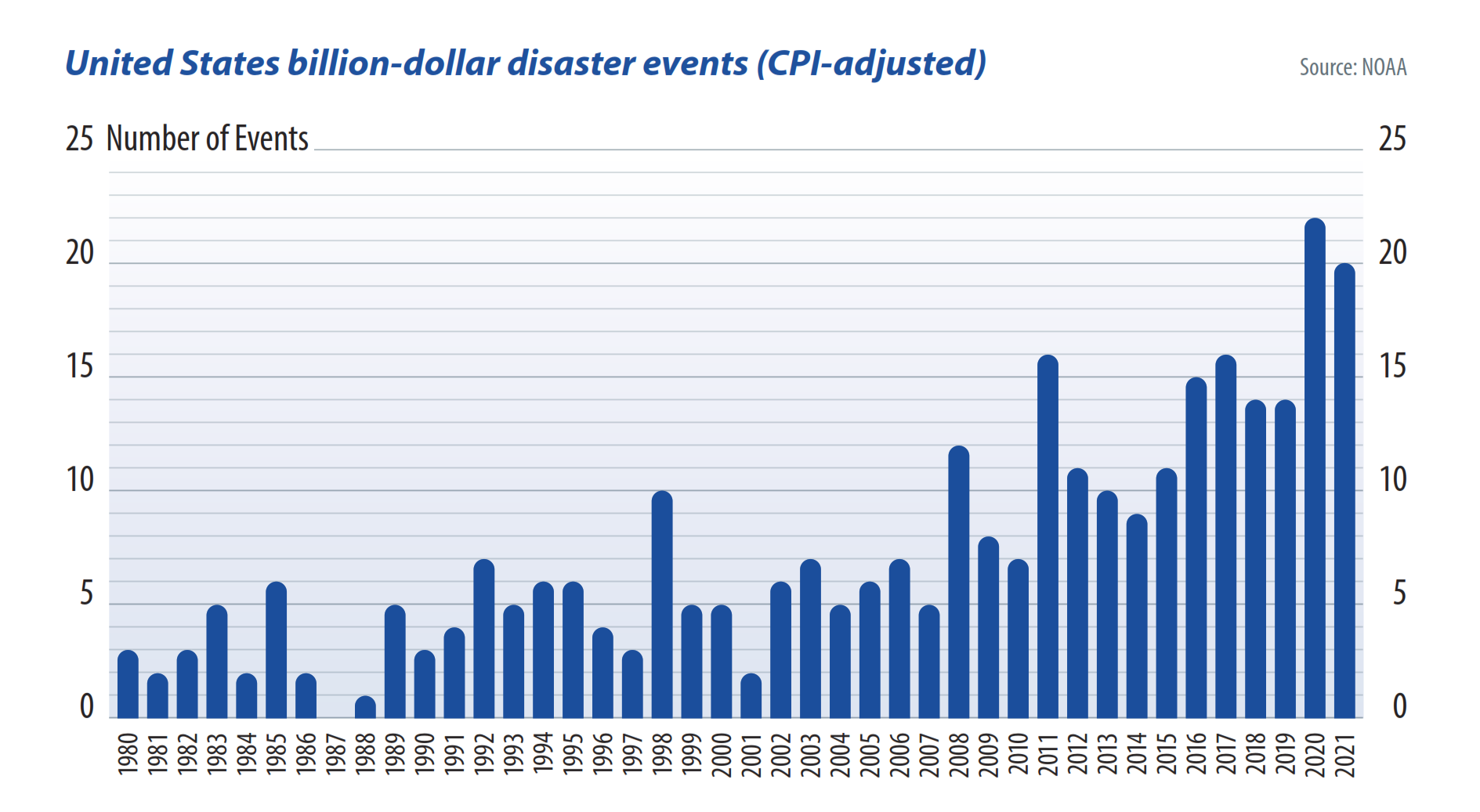

Many types of risk can keep solar and storage project developers up at night. One is the potential threat of natural disaster. As we’ve seen in recent years, the warming climate is associated with more frequent and stronger hurricanes, floods, hailstorms, and wildfires, which can imperil the very clean energy projects working to slow climate change in the first place.

Such disasters have already reshaped the insurance industry in recent years. A major disruption in the solar insurance market occurred in 2019, when a particularly violent hailstorm in Pecos County, Texas, damaged more than 400,000 solar panels at the 178 MW Midway Solar Project. As pv magazine USA reported at the time, insurers began offering specific hail-related policies.

Then came the 2020 wildfire season in California, damaging two projects in Rosamond and one in Bakersfield, which was enough to result in large claims.

Electricity offtake agreements typically include “force majeure” clauses to cover catastrophic natural disasters, but even if an event is covered in a contract’s force majeure definition, there may still be challenges. First, it can be complicated to prove what damage was caused by the event rather than prior transportation, installation, and wear-and-tear incidents. Secondly, successful force majeure claims often still lead to significant financial loss. While it may be possible to receive relief from the provisions of the offtake agreement, the insurance proceeds are often not enough to cover the repairs to damaged equipment.

It’s critical to have clarity on what’s covered by force majeure clauses and insurance policies. With more severe hailstorms, tornadoes, hurricanes, flooding, and wildfires on the horizon, what other steps can developers take to mitigate the damage when disaster strikes?

Local knowledge

Mitigating natural disasters starts with knowing the site and adding a safety cushion around its particular risks. This could mean raising ground-mount racking higher than the code minimum level in the flood-prone US Midwest or prioritizing your vegetation strategy in the wildfire-prone West of the United States to minimize damage if a fire breaks out.

For a success story, consider the 75 MW solar plant powering Babcock Ranch in Florida, 12 miles from where Hurricane Ian made landfall outside Fort Myers earlier this year. Built in 2018 with climate resiliency in mind, its design exceeded even Florida’s stringent building codes. As a result, the plant weathered a near-category five storm with no damage and was able to return power to the community long before the overall grid was restored.

Component selection

Another best-practice move is to become intimately familiar with the limits and capabilities of the equipment you’re using. Many of today’s biggest US solar projects are being built in the corridor that connects West Texas up through Colorado, where extreme hail events are becoming more frequent.

The certification process for modules involves an ice ball or hail test but not all assessments are equal and the tests may not replicate harsh real-world conditions. For a project in a hail-prone region, it may be worthwhile to prioritize a manufacturer that exceeds the minimum requirements.

One area of particular concern is the strength of the glass in solar modules. The glass typically used has become thinner with the widespread use of bifacial modules, to save on weight. Paying a premium upfront for stronger glass could lower the risk of having to replace hundreds, or thousands of damaged modules.

Establish a baseline

What can you do if your system is already installed? Collect a trove of information. A prime example is electroluminescence testing, that can non-invasively identify whether you already have microcracks in your modules’ silicon cells. These small fractures are typically invisible to the naked eye and can occur during production, transportation, or installation.

The blunt force of hailstorms can cause microcracks even if the glass appears undamaged. Having an established pre-storm baseline of any existing microcracks to compare against post-storm testing could be the deciding factor in winning your insurance claim after an extreme weather event.

Cost-benefit analysis

Given the unknowns, it can be hard to judge where to draw the line between costly project overdesign and smart preparation for a weather calamity. Resiliency planning can add to your budget, but lowers the risk of having to replace a substantial portion of your system.

Rising insurance premiums are already reshaping project financials as premiums have risen 400% in some areas over the past few years, often for less comprehensive coverage than before. As the industry increasingly limits coverage for the most extreme weather events, insurance should be viewed as a last resort rather than as the sole strategy employed.

The probability of facing Mother Nature’s wrath in any given year may be low but, over your project’s 30 year-plus lifespan, even one bad year can wreck financial assumptions. Preparing for an abnormal event with common-sense measures now can help protect a project’s bottom line in the long run.

Paul Wormser is CEA’s VP, Technology.