Duty Bound: US Solar Navigates Choppy Tariff Waters

by Dan Shreve

This article was originally published in pv magazine - January 2023 edition.

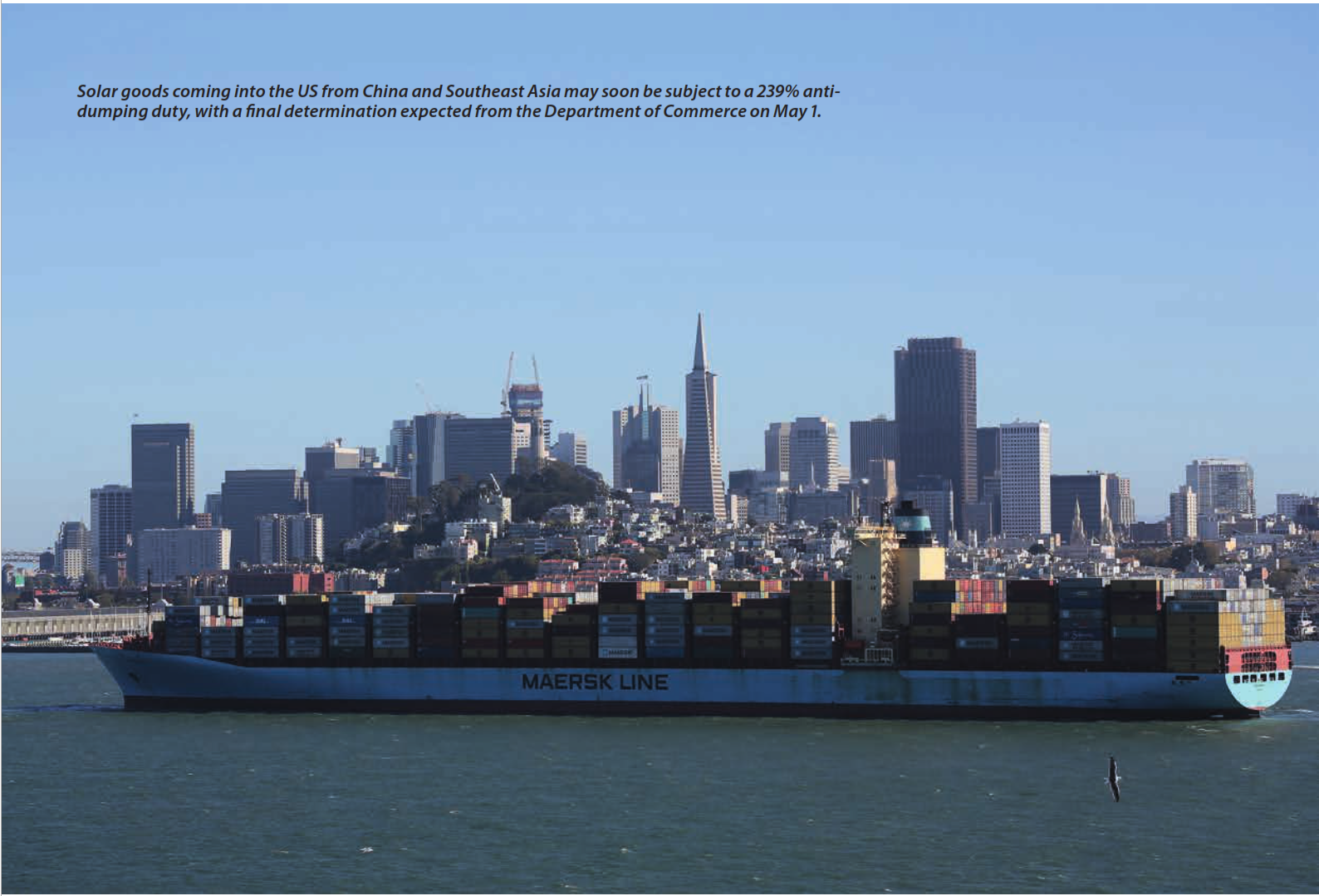

The Solar Energy Industries Association (SEIA) expects US solar additions to hit 15.7 GW in 2022, down 33% from 2021. Policy-driven supply constraints are the primary reason for the decline, as developers and original equipment manufacturers (OEMs) are struggling to navigate a raft of trade actions, including anti-dumping duties and measures to eliminate forced labor. Dan Shreve, vice president of market intelligence for Clean Energy Associates (CEA), reports.

To stop companies from circumventing trade duties, the US authorities introduced “anti-circ” measures. However, the US Department of Commerce’s preliminary findings of its investigation into cell and module imports from Southeast Asia have put said duties under the spotlight.

On April 1, 2022, the department began its probe into solar manufacturers whose goods are imported by US buyers from Cambodia, Malaysia, Thailand, and Vietnam. The investigation was opened after US manufacturer Auxin Solar alleged Chinese cell manufacturers are circumventing a 2012 anti-dumping and countervailing duty (AD/CVD) ruling by producing cells in Southeast Asia with Chinese-made wafers.

The commerce department recently found in favor of Auxin in a preliminary affirmative determination of circumvention and imposed anti-dumping duties of 239%, and undetermined countervailing duties, on dozens of companies operating in the four countries in question. Solar manufacturers BYD, Trina, Vina Solar, and Canadian Solar were excluded from the order.

The short-term impact of those tariffs, if confirmed in a final determination expected from the commerce department on May 1, will be mitigated by a holiday from anti-circ solar module tariffs introduced by President Joe Biden. That exemption will apply until June 2024. The recent ruling also set details for the scope of the investigation to permit cell and module makers to export to the US without paying duties, provided they use sufficient non-Chinese materials.

However, the longer-term implications of the commerce department’s findings would likely include the transition of supply chains, to minimize tariff costs where possible, and the continuation of multiple trade barriers in cases where the tariffs remain less expensive than the cost of changing supply chains.

A decade of trade-measure-related challenges for the downstream US solar industry started with an AD/CVD ruling by the commerce department to a complaint by German manufacturer SolarWorld in 2012. The intent of that ruling, and the subsequent use of Section 201 and Section 301 trade tariffs on imported PV modules, was to encourage a solar supply chain in the US. Instead, while few new domestic solar production lines have taken shape, increasingly dominant Chinese manufacturers have rapidly expanded into Southeast Asia.

In 2021, some 75% of US solar module imports came from Southeast Asia. Anti- circ moves have pushed this dynamic even further upstream and solar ingot and wafer supply is now ramping quickly in the region, with 22 GW and 29 GW of annual production capacity, respectively, expected to come online in 2023 and 2024.

IRA Carrot

Production incentives in President Biden’s Inflation Reduction Act (IRA) could foster the emergence of an integrated US solar supply chain but American manufacturers will come under strong cost pressure from Chinese and Southeast Asian suppliers. Once Chinese wafer OEMs relocate to Southeast Asia, in response to anti-circ measures, they may still undercut US rivals by using low-cost Chinese polysilicon. IRA shields from some of that impact via tax incentives but history tells us tax benefits, no matter how generous, may succumb to low-cost electricity, cheap labor, and foreign government subsidies.

The logical recourse for new, US-based OEMs will be to apply for trade protection. The wind industry has experienced this dynamic since 2011, when the commerce department initiated an AD/CVD investigation into wind turbine tower imports from China and Vietnam, on behalf of the Wind Tower Trade Coalition (WTTC). A year later, the department levied AD rates of 45% to 71% against Chinese and Vietnamese tower OEMs. Chinese OEMs were subject to CVDs ranging from 22% to 35%.

As a result, wind turbine tower production for the United States shifted to Asian nations such as South Korea and Indonesia. Low-cost production there prompted the WTTC to lodge another complaint and the commerce department issued a final determination in 2020, resulting in duties of 5% to 9% against South Korea and Indonesia, respectively. The scramble for low-cost supply resulted in the commerce department issuing yet another determination on behalf of the WTTC. This time, tariffs of 54% to 94% were levied against India, Malaysia, and Spain.

The medium-term future for US solar is far from clear and could take many paths: a resumption of the import duties and tariffs cycle, further IRA-style support, cost increases for overseas manufacturers that narrow, or eliminate their competitive advantage, or new technology to fundamentally alter the dynamics that have dominated the industry for a decade. CEA estimates China - and Southeast Asia based solar manufacturers will enjoy a cost advantage ranging from $0.11/W to $0.14/W over US peers before trade tariffs and incentives are applied.

If government policy drives up the market price of modules imported by the United States, to match the domestic cost premium, those higher prices will lead to slower deployment. Yet, as we have seen over several years, there are likely to be more unanticipated developments in global supply chains that the industry will have to adapt to.

Dan Shreve is CEA’s VP, Market Intelligence