Anomaly Identified During Inspection of 1 GW Solar Project

SUMMARY

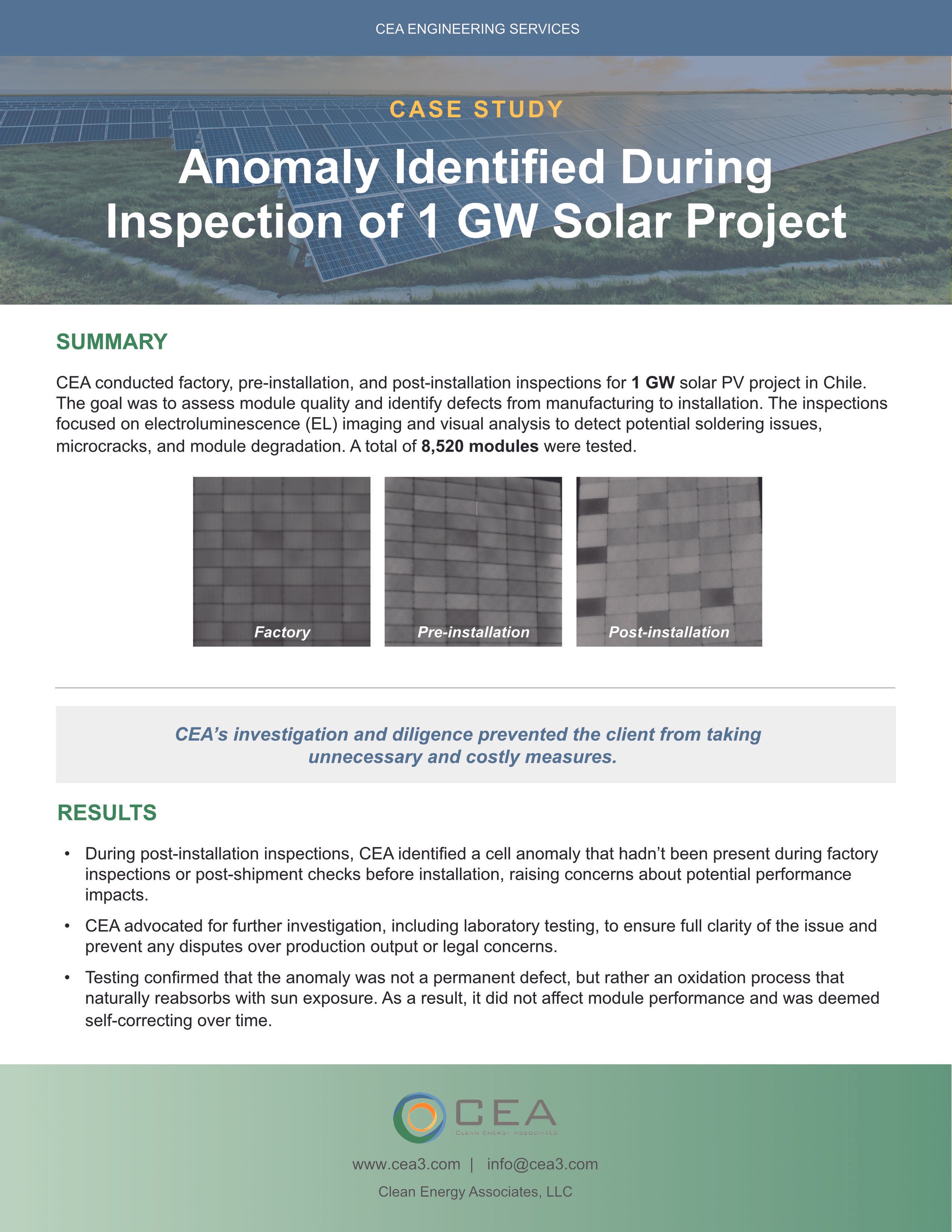

CEA conducted factory, pre-installation, and post-installation inspections for 1 GW solar PV portfolio in Chile. The goal was to assess module quality and identify defects from manufacturing to installation. The inspections focused on electroluminescence (EL) imaging and visual inspection to detect potential soldering issues, microcracks, and other module degradation mechanisms. A total of 8,520 images were taken.

EL images taken in the factory, post-installation, and in the laboratory

As a result of CEA’s investigation and diligence, a hidden risk was revealed to the client, along with suggested mitigation measures.

RESULTS

During post-installation inspections, CEA identified a cell anomaly that hadn’t been present during factory pre-shipment inspections or post-shipment checks before installation, raising concerns about potential performance impacts.

CEA advocated for further investigation, including laboratory testing, to ensure full clarity of the issue and prevent any disputes over production output or legal concerns.

Testing did not confirm an initial suspicion about cold soldering (cell contact not being fully soldered). The theory provided by the supplier, that the effect was due to testing conditions on site or would go away after light exposure could also be rejected based on the carried-out experiments. As the module performance was not impacted beyond the warranted ratings, CEA recommended further laboratory testing to identify the root cause and proposed regular inspection of the suspicious modules.