pv magazine test: November 2023 Results

By George Touloupas

This article was originally published in pv magazine – February 2024 edition. Learn more about the pv magazine test here.

George Touloupas, senior director of technology and quality at Clean Energy Associates (CEA), analyzes the November 2023 energy yield results from the outdoor testing field in Xi’an, China. He also looks at some upgrades to the rooftop system, as new modules featuring the latest negatively doped, “n-type” technology join the program.

With more modules and a range of different dimensions and electrical specifications expected to join our program in 2024, it is high time for an upgrade to our pv magazine test installation. For this purpose, the plant was taken offline in the second half of November 2023, meaning the results show only 14 days of data for the month. We will introduce details of our outdoor field upgrade in the second part of this article.

During the adjustment period, three new modules using different technologies completed the first round of laboratory testing and are set to be added to the outdoor array. Results for the indoor testing of these modules – a positively doped “p-type” back contact panel, a tunnel oxide passivated contact (TOPCon) product, and a heterojunction (HJT) device – are published on pv-magazine.com. Meanwhile, more products are making their way through the indoor test stages as we write and will be added to the outdoor array in due course.

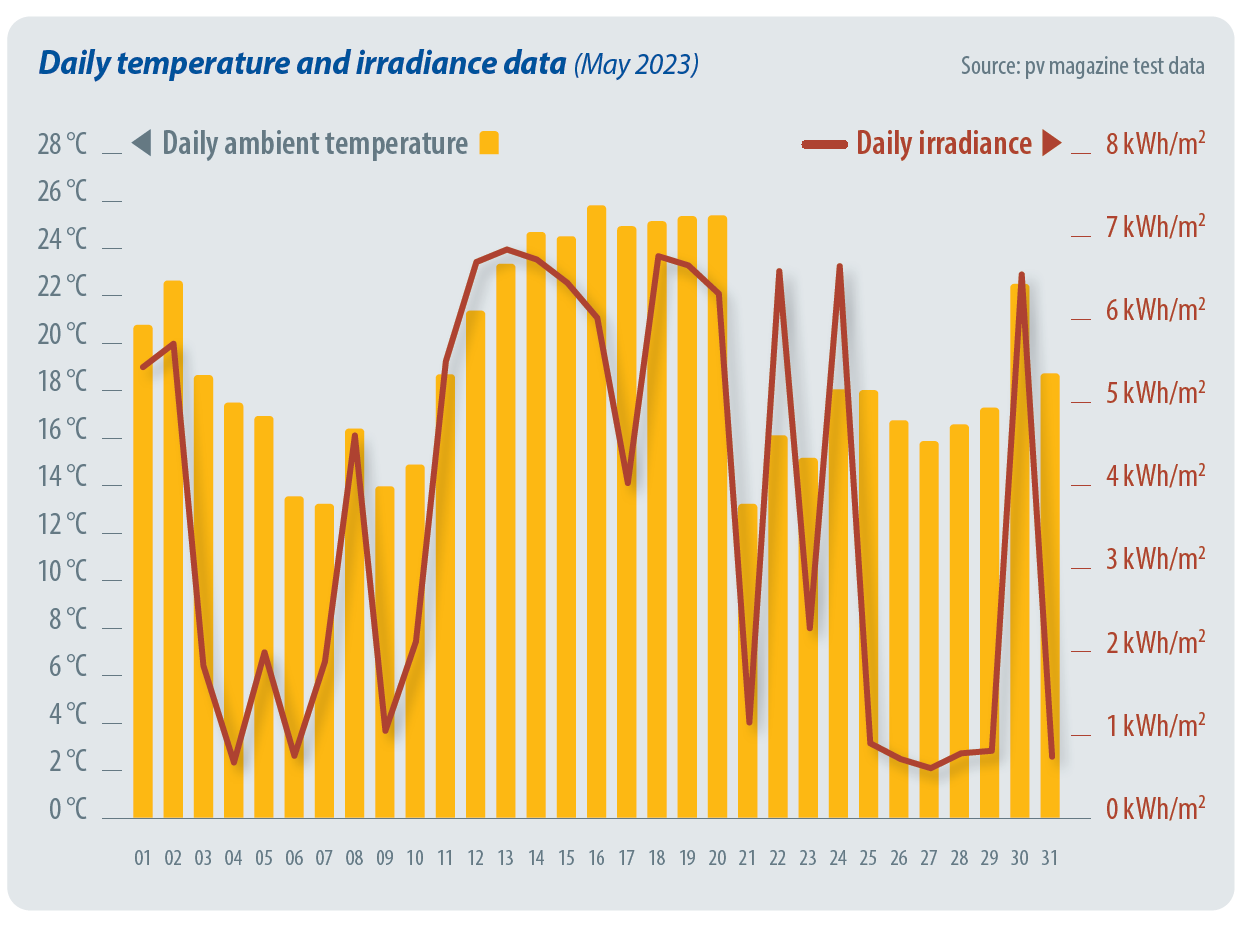

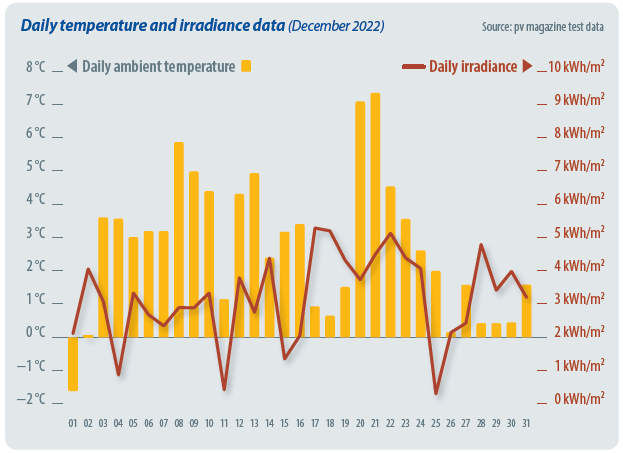

The first chart below provides the irradiance and ambient temperature data for November 2023. Products with advanced cell technology such as nTOPCon, nHJT and back contact are beginning to make up a larger share of our product pool, leading to obvious performance deviations with respect to PERC. Hence, we decided to group products with similar cell technology together and report different technologies separately.

Figure 1: Daily temperature and irradiance data - November 2023

The average bifacial boost was 4.69% for November 2023. Bifacial boost is the relative advantage of the average specific energy yield of all bifacial products compared to the average specific energy yield of all monofacial PERC products.

Table 1: Bifacial boost - August to November 2023

Table 2: Specific energy-yield ranking of n-type bifacial (TOPCon and HJT) modules - November 2023

Table 3: Specific energy-yield ranking of bifacial PERC modules - November 2023

Table 4: Specific energy-yield ranking of monofacial modules - November 2023

Figure 2: Specific energy yield of n-type bifacial (TOPCon and HJT), bifacial PERC, and monofacial modules - November 2023

Figure 3: Relative yield of different technologies - November 2023

Energy yield measurements

The energy yield comparison among various technologies, including bifacial boost, is analyzed using products installed after the beginning of 2019.

The energy yield is given in Wh/Wp and calculated by dividing the energy produced by the module by its maximum power point (Pmax) at standard test conditions (STC) for the module. This Pmax is the maximum STC power after a process of stabilization. • The results are grouped into categories, per module type.

The bifacial boost depends on many parameters: bifaciality factor, installation geometry, albedo of the ground, the sun angle and diffuse irradiance. The ground, in this case, is gray gravel.

System upgrades

To improve measurement accuracy and prepare for a larger number of products, we have upgraded various aspects of the outdoor test system, including its mounting system and inverters, as well as the systems used to measure module performance. As new, larger-sized samples join our test program, we have detected some shading risks at the edges of modules in mornings and evenings, the effects of which we previously had to filter from the published results. To eliminate this effect, and to create space for more samples, we decided to rearrange the layout of all samples with different dimensions. The new layout is explained in the schematic below.

We have reinstalled, and will now install all new modules horizontally, except some special products, such as Longi’s hybrid passivated back contact (HPBC) products, which have self-cleaning properties that depend on orientation. In addition to the change of module layout, we reduced the tilt angle of our mounting structure to reduce the risk of shading.

“We have upgraded various aspects of the outdoor test system, includingits mounting system and inverters.”

— George Touloupas

We also took advantage of the break to conduct regular calibration of the energy meters. It is important to note that in our outdoor field, consistency among various meters is more important than the absolute accuracy of each meter. A pre-calibrated, high-accuracy meter is used as a reference standard meter. After checking the data, the largest deviation among various meters was about 1.2%. We consider this deviation good enough for our outdoor test field program.

Figure 4: pv magazine test outdoor layout

New microinverters

As the pv magazine test program receives more high-power modules from various manufacturers, high-capacity microinverters are needed to support these products. At the end of 2023, a new microinverter type, the HMS series from Hoymiles, was introduced to the test field (see boxed text below.)

All products in our test field are now connected to the HMS- 1800B microinverter. One of the advantages that led us to choose this product is its two MPPTs with four pairs of input connectors design, plus the ability of ‘Y-connecting’ two pairs of connectors in parallel to support high current modules. With this flexibility, we will be able to support both high power and low power modules with the same microinverter type while ensuring there is separate MPPT for each product. This renders our system design much more convenient for maintenance, and it also helps to reduce performance deviation among different products due to hardware differences. We evaluated the performance of this inverter by connecting two modules from the same type and batch, and with a very similar STC power rating, to different MPPTs and observing the performance deviation after a period of operation. The Wh/Wp difference between two MPPTs is below 0.8%, which also includes the maximum power difference between two samples. This result enhanced our confidence in the reliability of the setup and measurement accuracy of our outdoor testing system.

High-powered solution

Photo: Hoymiles

Upgrades to the pv magazine test system include the addition of the Hoymiles HMS series microinverters – the latest four-in-one microinverters from the Chinese manufacturer. They come with 2,000 volt-amps of output power, allowing integration with up to four panels, each with independent maximum power point tracking (MPPT) and monitoring capabilities. The HMS series includes a sub-1 gigahertz wireless connection, ensuring stable, uninterrupted communication. Hoymiles says the product is designed for easy installation and simplified maintenance, thanks to its Flex cable system. The manufacturer says this system is inspired by toy building blocks and ensures a straightforward setup without complex wiring or interconnection – reducing installation time by up to 70%. The product features rapid shutdown capability and an isolated transformer and conforms to other industry standards.

Test Cooperation

pv magazine test is a cooperative effort involving pv magazine, CEA, Gsolar and Hoymiles. All testing procedures are carried out at Gsolar’s test laboratory in Xi’an, China. CEA supervises these tests and designed both the indoor and outdoor testing procedures.